Omni Mixing Technology™

Proprietary, feedback-controlled dosing that measures and adjusts every liter in real time — delivering consistent strength, lower waste, and fewer rejected loads.

Performance at a Glance

Throughput Capacity

Cement Accuracy (by Mass)

Average CO₂ Reduction vs Batch

Zero Rejected Load*

*Based on internal QC logs; request a demo to validate against your mix.

How It Works

Closed-loop control with live sensors and auto-correction keeps yield and water/cement ratio on-spec — even as material conditions change.

1) Measure

High-resolution sensors track cement, water and admixtures in real time.

2) Compare

Target vs actual computed per liter; deviations flagged instantly.

3) Adjust

Dynamic dosing corrects flow to maintain spec — no drift.

The Technology

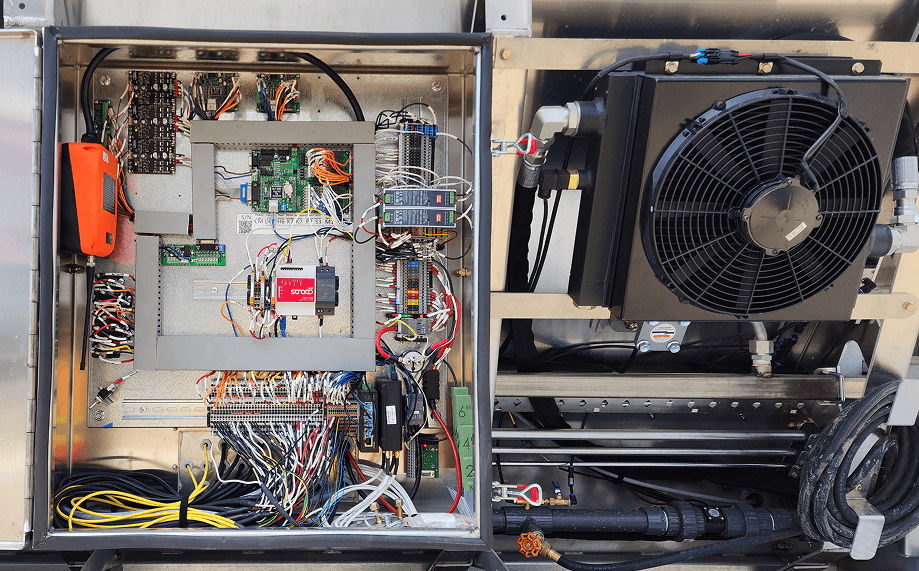

Dynamic Feedback Control

Control loops regulate cement, water and admixtures in milliseconds to keep yield and w/c ratio dialed.

Mix Design Library

Save, lock and recall approved designs with role-based access and tolerance enforcement.

Telemetry & QC

Exportable logs for DOT/owner transparency and internal compliance via CloudOps™.

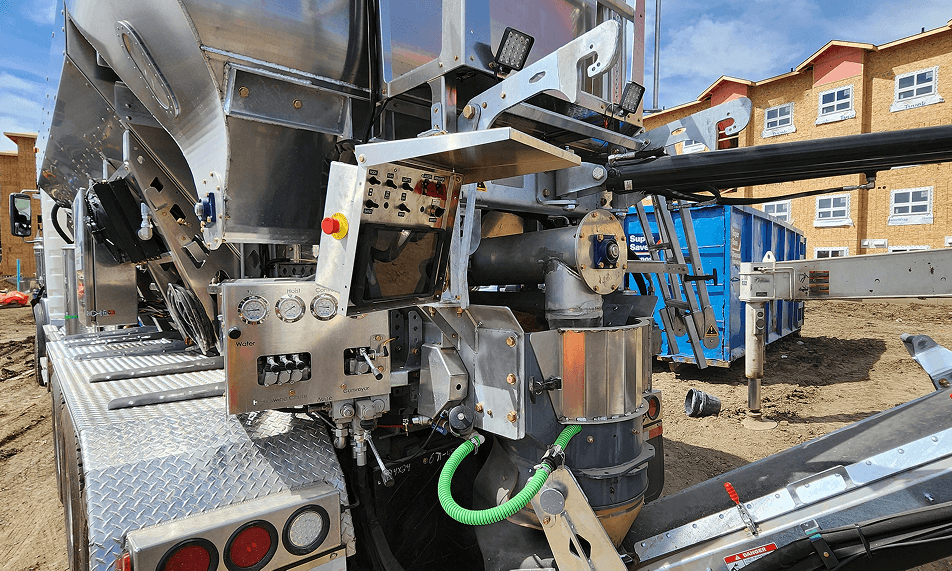

Modular Hardware

Swap hoppers, pumps or controls fast. Less downtime, more uptime — adaptable for every mix.

Proof & Validation

Field Data

100+ yd³/hr throughput on highway and industrial projects across North America.

QC Logs

11 years of QC with zero rejected loads across active deployments.

Third-Party Testing

Independent partners available for yield, slump and strength verification.

Owner Feedback

DOT & EPC clients cite predictable strength, reduced waste and improved schedule control.

See It on Your Specs

Request a live demo with your target strengths and admixtures — our team will bring the data.

Request PricingOur Mixers

Help The Environment By Saving You Money

Our mixers are built for longevity, efficiency, and sustainability, reducing waste while delivering precise, high-quality concrete. With durable construction and optimized material usage, we help you build stronger, smarter, and more sustainably for decades to come.

Concrete On Tap - Less Resources Used, More Money In Your Pocket

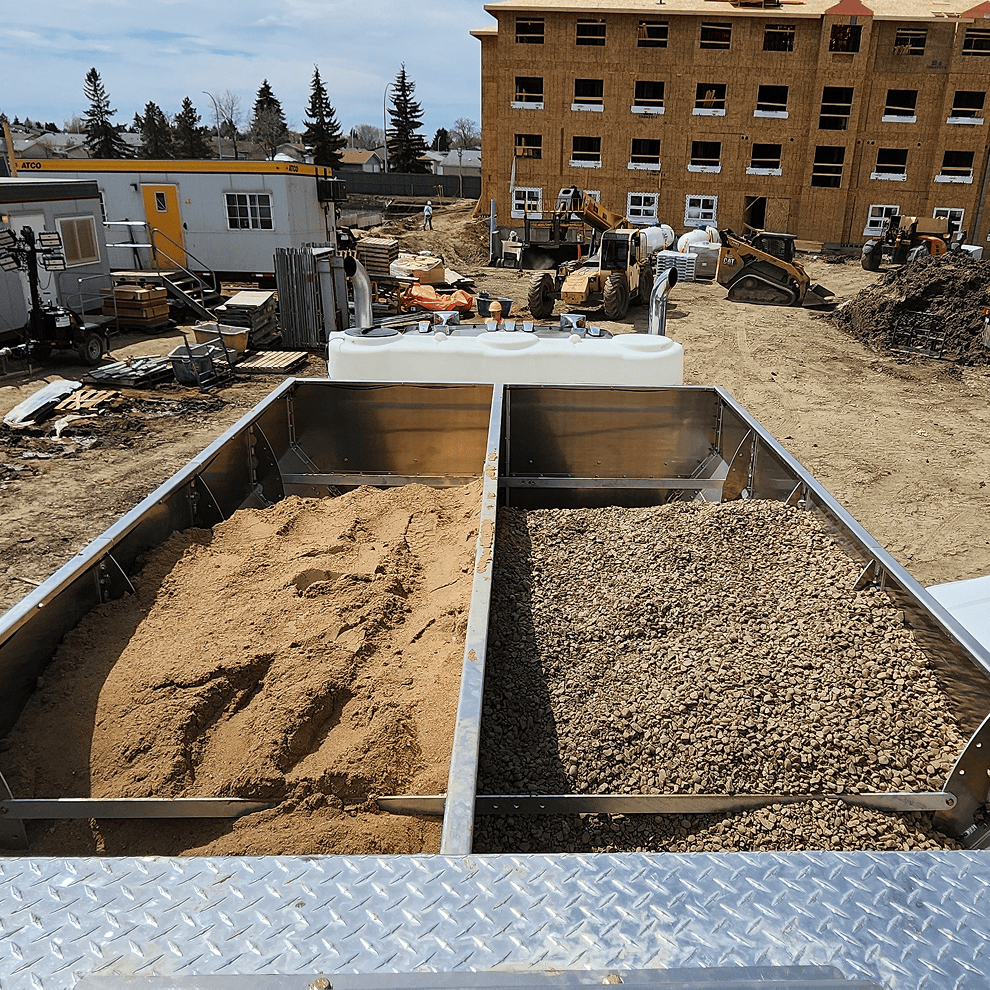

Our mixing technology reduces CO2 emissions by 10-17%, the water used for washout, and the amount of cement powder used in your pours. Thanks to our technology, you can use admixtures more effectively while reducing the cement content for your mix to get to the same strength because of the accurate dosing and mixing of your materials.

Modular Design - The Mixer You've Only Got To Buy Once

Our mixer will last the lifetime of your operation and is fully upgradable, which means that you don't have to throw it away when parts wear out. You just replace the components that need to be replaced or upgrade the components that need to be upgraded to have the latest and greatest mixer.

Concrete Genius - Your Partner In Crime

We're concrete experts, and we'll be here with you every step of the way to ensure your success. We did not build this mixer so you'd be back to buy another one in 10-15 years. We designed it believing that you'll be in business for the next 20-30 years and you don't want to have to replace it.

We've Put Our Technology Through

The Most Rigerous Development Process On The Market

Over the last 11 years, our technology has been embraced by countless different government bodies and industries.

The technology is currently beyond any other platform on the market, but we’re just getting started.

- Public Schools

- Airport Runways

- Oil Sand Facilities

- Public Roads

- Swimming Pools

- Many, many more...

Chock-Full Of Solutions That Fit Your Needs

Dynamic Feedback Control

Complete accuracy is ensured with our prioritary technology that constantly tests and measures the concrete thousands of times per cubic meter and adjusts according to the project’s specifications, ensuring the most accurate and consistent concrete possible.

Concrete CloudOps Technology™

Assured Admixture Admission

Let's Talk Mixing Technology

- 4001 Elleffson St, Athabasca, AB, T9S 1T7, Canada

- 780-675-9819

- 8am-5pm MST Mon-Fri