OMNI Mixing Technology™

Proprietary, feedback-controlled dosing that measures and adjusts every liter in real time—delivering consistent strength, lower waste, and fewer rejected loads.

Performance at a Glance

*Based on internal QC logs; request a demo to validate against your mix.

How It Works

Closed-loop control with live sensors and auto-correction keeps yield and water/cement ratio on-spec—even as material conditions change.

1) Measure

High-resolution sensors track cement, water and admixtures in real time.

2) Compare

Target vs actual computed per liter; deviations flagged instantly.

3) Adjust

Dynamic dosing corrects flow to maintain spec—no drift.

The Technology

Built for precision, reliability, and long-term performance

Dynamic Feedback Control

Control loops regulate cement, water and admixtures in milliseconds to keep yield and w/c ratio dialed.

Mix Design Library

Save, lock and recall approved designs with role-based access and tolerance enforcement.

Telemetry & QC

Exportable logs for DOT/owner transparency and internal compliance via CloudOps™.

Modular Hardware

Swap hoppers, pumps or controls fast. Less downtime, more uptime—adaptable for every mix.

Proof & Validation

Field Data

100+ yd³/hr throughput on highway and industrial projects across North America.

QC Logs

11 years of QC with zero rejected loads across active deployments.

Third-Party Testing

Independent partners available for yield, slump and strength verification.

Owner Feedback

DOT & EPC clients cite predictable strength, reduced waste and improved schedule control.

See OMNI in Action

Watch how our feedback-controlled mixing delivers consistent results in the field.

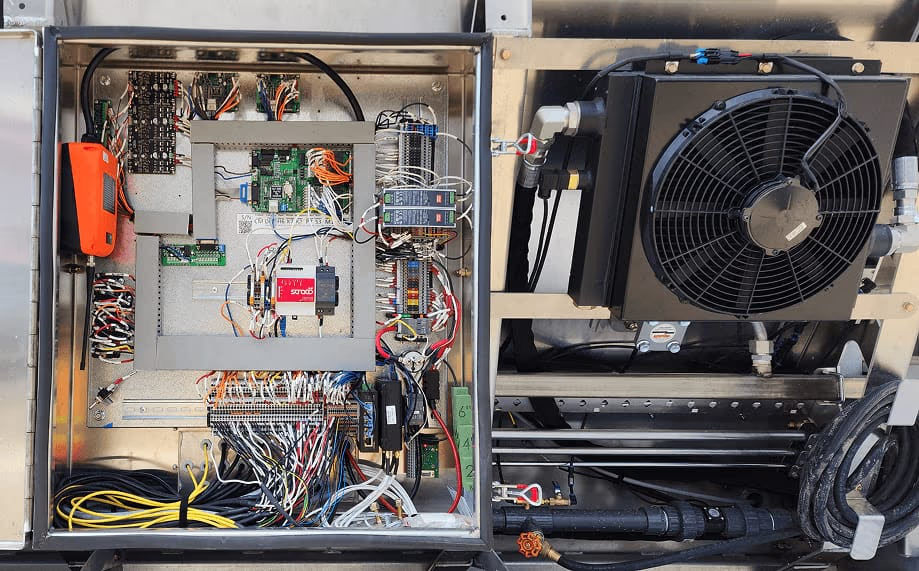

Built for the Field

Water- and dust-proof electronic control systems keep operations running in harsh conditions. Modular design means easy maintenance and upgrades.

- Rugged enclosures and sealed connections

- Real-time diagnostics and telemetry

- Swap components without replacing the whole system

See for Yourself

OMNI mixers on job sites across North America.

Why OMNI

Less waste, more control, built to last

Concrete On Tap

Reduce CO₂ by 10–17%, cut washout water and cement use. Accurate dosing and mixing let you hit strength with less material and more effective admixtures.

Modular Design

Built for the life of your operation. Replace or upgrade components as needed—no need to replace the entire mixer.

Your Partner

We're concrete experts and we're with you every step of the way. We build mixers to last decades, not to be replaced in 10–15 years.

See It on Your Specs

Request a live demo with your target strengths and admixtures—our team will bring the data.